English

English

This is a modal window.

Vulcanization accelerator pre-dispersion masterbatch DCBS-80 can prolong the scorching time of rubber, provide high processing safety and fast vulcanization speed. It can be used alone in low sulfur vulcanization, and also used with dithiocarbamate or thiuram type accelerator, the resulting vulcanized rubber has good aging resistance and compression permanent deformation resistance.

Send InquiryChemical Name: N,N-Dicyclohexyl-2-benzothiazolsulfene amide

Trade Name:XUANNUO®DCBS-80GE F140

CAS:4979-32-2

| Specifications: | |||

| Item | Standards | ||

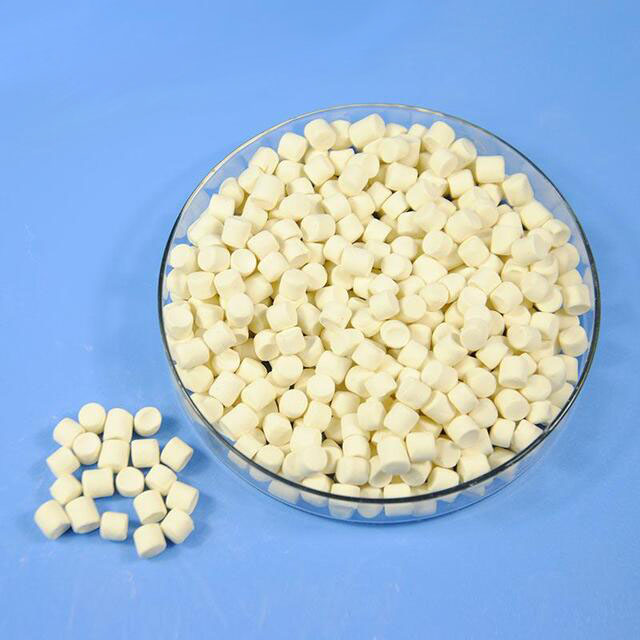

| Appearance | Beige Granules | ||

| Active Content (%) | 80.0 | ||

| Filtration (μm) | 140.0 | ||

| Binder | EPDM/EVM | ||

| Sulfur Element (%) | 14.8 | ||

| Density (g/cm3) | 1.03 | ||

| Melting point | Min 97℃ | ||

| Purity | Min 98% | ||

| Free amine content | Max 0.4% | ||

| Ash content(950℃,2h) | Max 0.3% | ||

| Volatile content | Max 0.3 % | ||

| 63μmsieve residue | Max 0.5% | ||

Applications:

The mechanical properties of the vulcanizate of DCBS, especially the dynamic properties, are relatively good, and the elasticity and constant elongation are high. Because vulcanizate has a bitter taste, it is not suitable for making rubber products that come into contact with food. The main application is to be used in the manufacture of tires, tapes, shock absorption products, and backing compounds for retreading tires. The general dosage is 0.5-1 part, and the sulfur is about 2.5 parts. The product is low toxicity.Dust free products with a complete filtration up to 100µm, no skin sensitization, health guard of operators.

Package: 25kg/bag.600kg/pallet

Neutral packing, Xuannuo Style Packing, Customized packing

Storage & Shelf Life:Stored in a dry and cool place. 1 year in its original packaging

Copyright © 2025 Henan Xuannuo Chemical Co., Ltd All rights reserved