English

English

DOTG-75GA F140 can be used for natural rubber, diene synthetic rubber, DOTG causes a very slow vulcanization start and relatively slow vulcanization rates. The use of DOTG alone can cause severe vulcanization reversion, so an effective antioxidant is required.

Send InquiryChemical Name: Di-o-tolylguanidine

Trade Name:XUANNUO®DOTG-75GA F140

CAS:97-39-2

| Specifications: | |||

| Item | Standards | ||

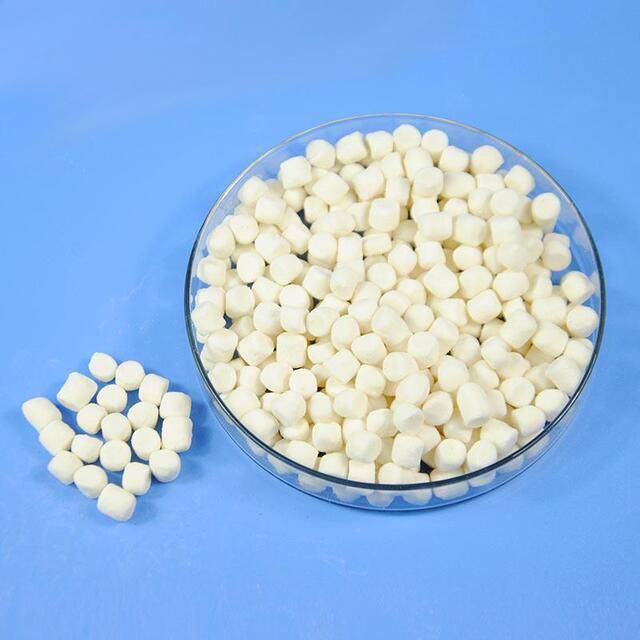

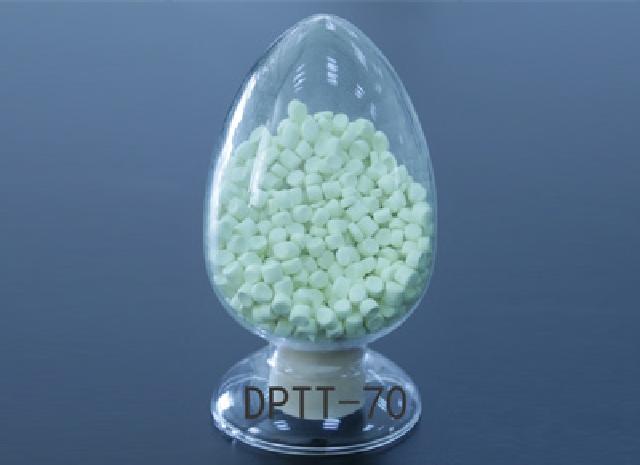

| Appearance | Grey-white to Beige Granules | ||

| Active Content (%) | 75.0 | ||

| Filtration (μm) | 140.0 | ||

| Binder | ACM | ||

| Nitrogen Content (%) | 12.5 | ||

| Density (g/cm3) | 1.10 | ||

| Melting point | 167℃ | ||

| Purity | Min 96% | ||

| Ash content | Max 0.4% | ||

| Volatile content | Max 0.5% | ||

| 63μmsieve residue | Max 0.5% | ||

Applications:

DOTG can be obtained by hydrolysis of cyanogen chloride and o-toluidine after reaction, or by the action of o-toluidine and carbon disulfide to form di-o-tolylthiourea, and then desulfurized with lead oxide in ammonia water. Can be used for natural rubber, diene synthetic rubber.Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thankstofiltration.Wider compatibility with other elastomers.

Package: 25kg/bag.600kg/pallet

Neutral packing, Original packing, Customized packing

Storage & Shelf Life:Stored in a dry and cool place. 1 year in its original packaging

Copyright © 2025 Henan Xuannuo Chemical Co., Ltd All rights reserved